So I painted and did my side of the closet, I made my better half do the other side. I do believe it took her longer to do her side than it did me the whole thing but it’s almost done.

Author: aron

-

Happy New Year – New Closet

Well we’ve finally made it down to last day of this insane and surreal year. 2020 could not end soon enough and it finally has. So there are no parties, no gatherings, what to do with the evening? I know! Let’s redo the closet in the master bedroom!!!

So that’s what I did for new years eve, I had the paint, sanders, take down equipment, spackle and most importantly a closet organizer I order a year ago.

Happy to say I’ve got it complete and the clothes were actually hung back up by the time I went to bed. -

Replacement Air Compressor

So with the impending build of the shed imminent, it’s time to procure the tools to get er done. While my Craftsman 30 gallon compressor has served me well for many years (close to 20 I believe), it looks like the motor has given out, they don’t make the motor anymore and Craftsman and Sears are about as dead as the motor. So it’s time to upgrade. I needed something that takes up less space (upright) and I found it in the Husky C271H. $358 at Home Depot, it’s 5.1 CSFM @ 90PSI so should be good for the framing, inflating and roofing needs I have. It’ll run my impact guns and air ratchets, maybe a little light for sanding and such but that’s not what I’m needing it for. I need to buy the nail guns but I think this fits the bill for a home construction tool.

-

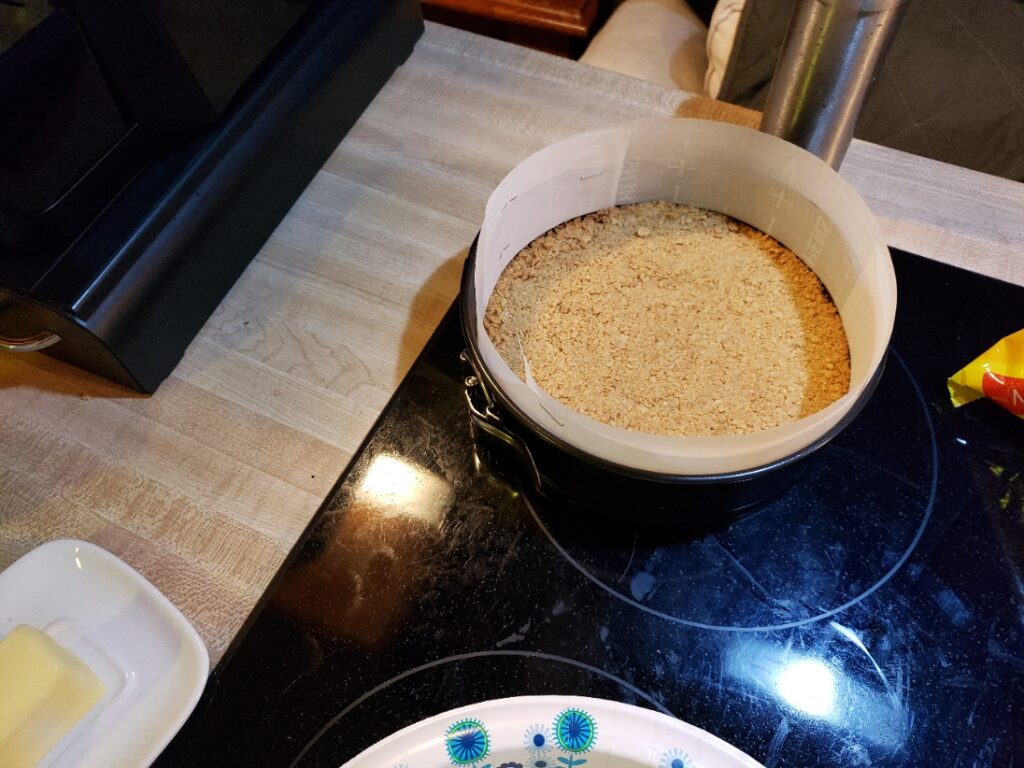

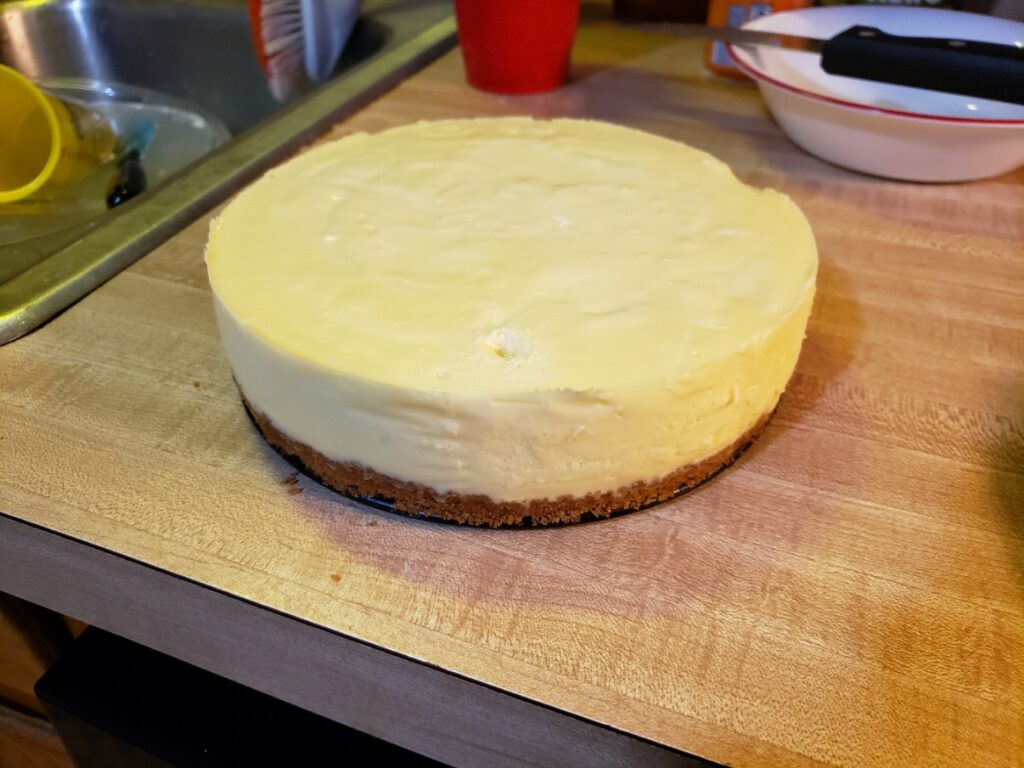

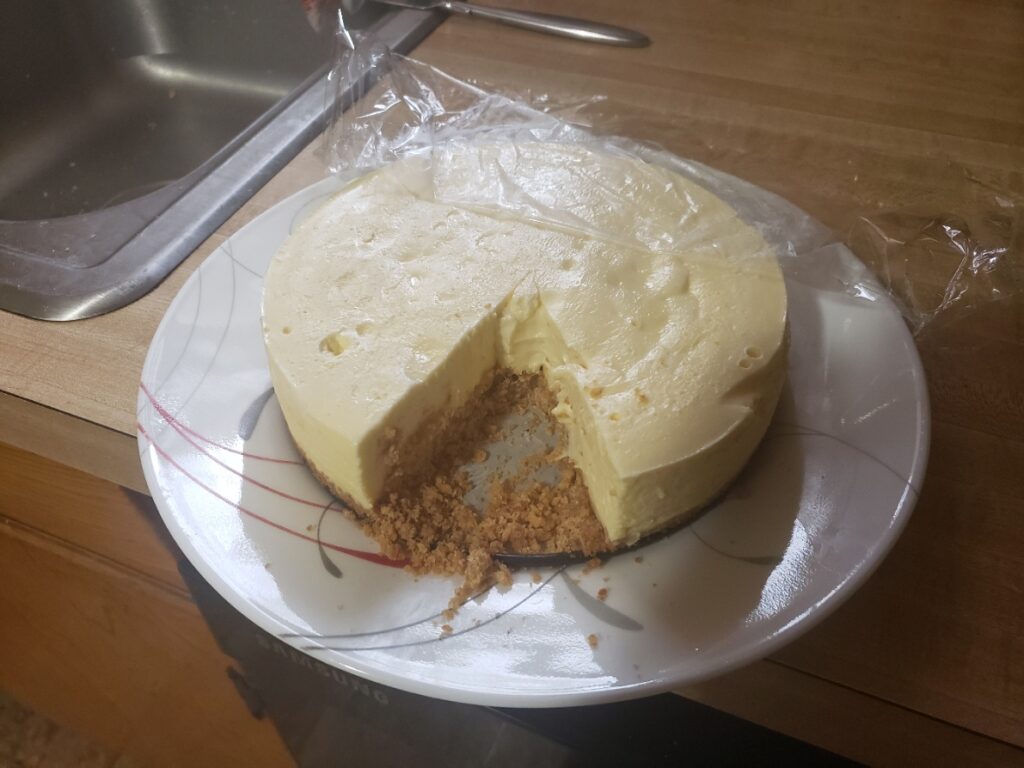

Instant Pot Cheesecake

So since I was a kid I’ve loved the tangy sweet delight that’s known as cheesecake. Mom used to make a cheesecake for the Octoberfest at TCCC, I was 8??? In any case I’ve always loved it but making it seemed a daunting and downright impossible task. Even Alton’s episode left me despondent that it was just downright too hard to make. Fast forward to the current. When I bought my instant pot, I got an accessory kit that had a steamer basket, egg holder, fridge magnets with times and oddly enough a spring form pan. I knew this was the tool for cheesecake but in an instant pot???

Turns out the answer is emphatically yes. The steam is the perfect way to cook cheesecake and the pressure doesn’t hurt either. I found this recipe which I’ll shamelessly copy for my food blog shortly. Give it a shot, it’s well worth the effort.

-

Pizza Subs

So having done time in Erie, PA, I’ve developed a taste for pizza subs. Now you’d think this would be an easy order to fill. Any place with sub rolls and pizza fixings should be able to build this, or so you would think. But alas there’s no one willing to do this. There was one place I found down here (Dino’s) that used to have it on the menu, while it lacked a je ne sais quoi that was found in abundance at any hole in the wall Italian place in Erie, it did pass the bar and fit the need. But they stopped making them, when they said they no longer had it on the menu I asked them what they didn’t have, it stymied the order taker and I gave up. But you can make them on your own and here’s the proof:

-

Leaf Clean Up

Well today was good day, it started off well enough, I pulled out the leaf vac and was cleaning up the front beds, watered the shrubs and then spiked them with a fertilizer spike. They’re beginning to come in pretty good but heck they’ve been in there for 4 years now. Some slight drama at the kids place but things seem to have worked themselves out for now. Couldn’t have asked for a better day weather wise and the Cowboys got a real win. Not bad for a Sunday!

-

Pavers 1st Move Finished!!!

So the pavers are complete, a scant 2 weeks after they were dropped off. Oh well, it was never about speed, this is a slow progress but high quality. So now that we have the back yard work area ready, the next steps are, repair air compressor, order tools, order materials, build. Stay tuned for progress as it becomes available.

-

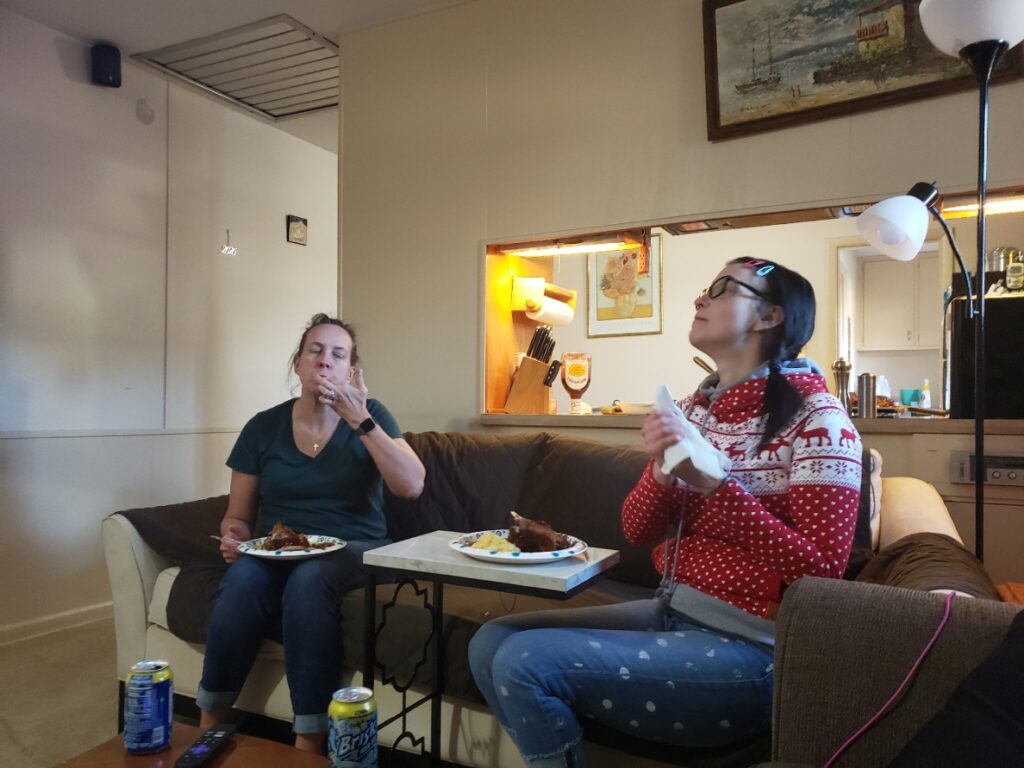

Christmas Day

We slept in and then started the cooking, we had ribs, baked beans, something that was supposed to be au gratin potatoes but came out like cheesy mashed potatoes. But a good time was had by all.

-

Merry Christmas!

It’s Christmas eve and we just got back from my sisters where we had filet magnon with baked mashed potatoes and broccoli and carrots. Mom, Sandy, Cortney, Garth, Jason and I had a wonderful time.

-

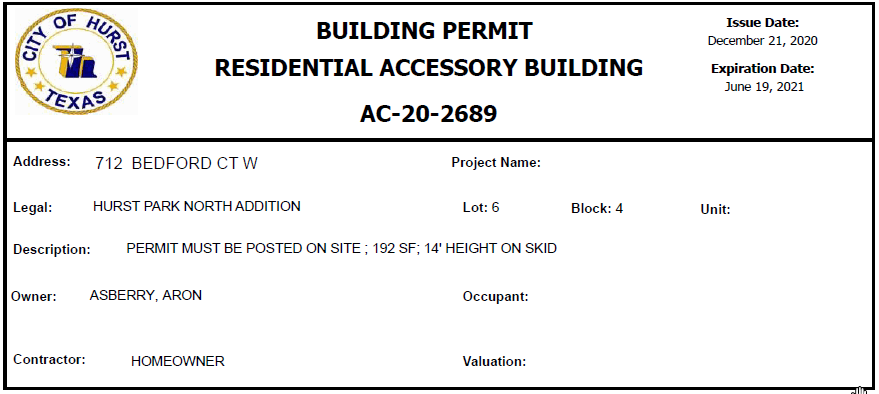

Permit Acquired

This should be a celebrated moment in my adulthood! I actually got a permit to build the shed! Now mind you the only reason I went to the trouble with this is because the shed is on the back of the property and there’s an easement back there and I wasn’t sure how far away to build. I don’t generally support or even condone the government getting in your business as to what you do with you’re property by requiring permits but made an exception in this case because I don’t want to have to move it:)